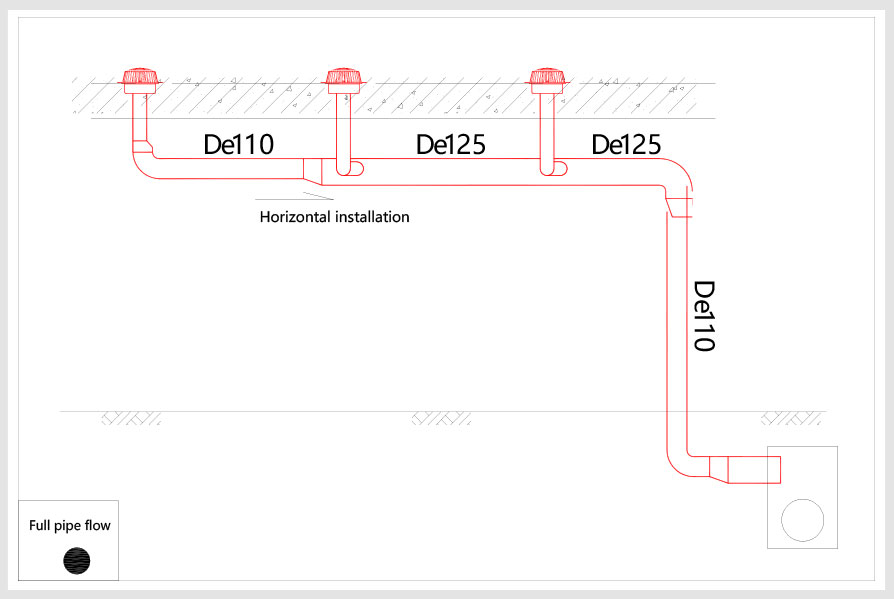

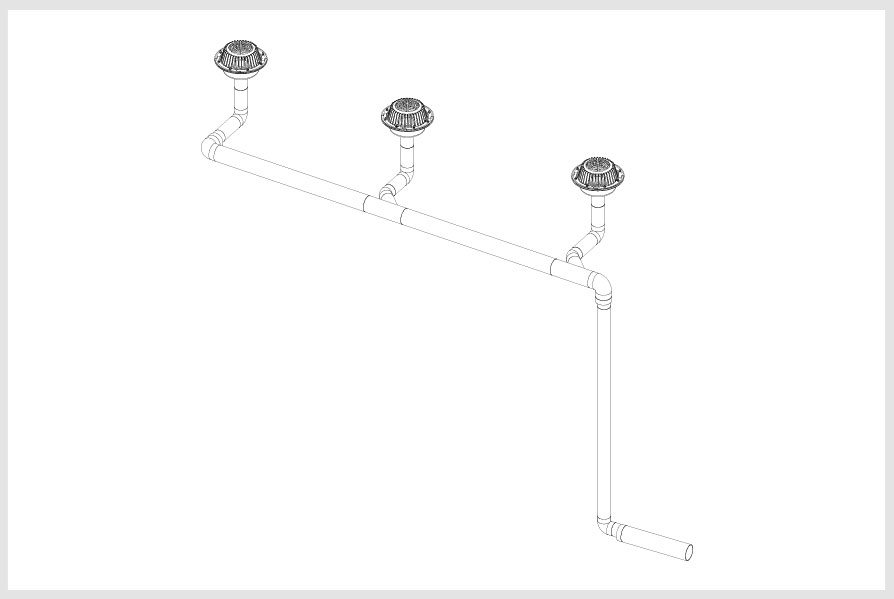

In respect of the siphonic rainwater drainage and collection systems, the siphon action shall be formed by full use of the energy produced from the altitude difference between the roof and the ground that is carefully calculated by use of the “Bernoulli” equation, in which the system would rapidly discharge the rainwater in the full flow state and provide convenience for the subsequent rainwater collection.

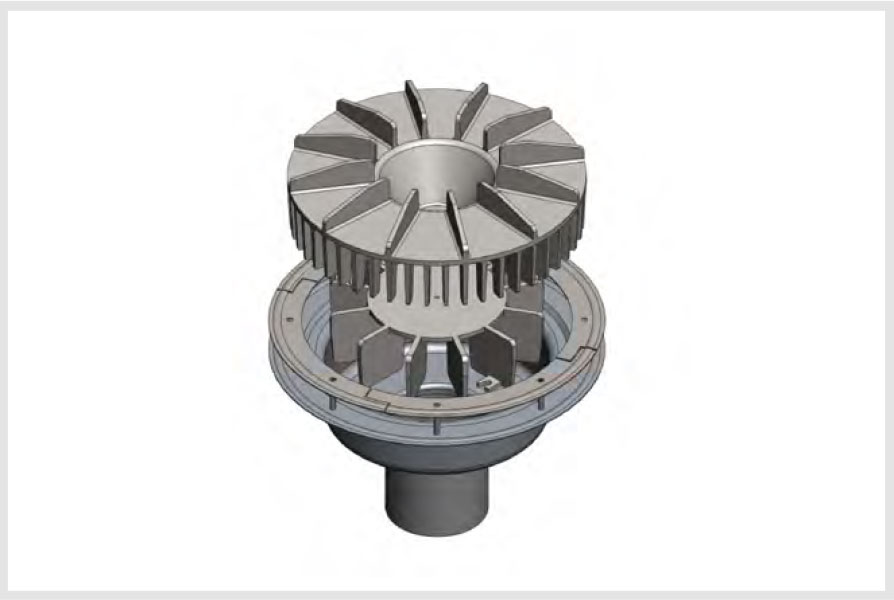

As the core product of the system, it adopts the unique backward eddy current device, in which the rainwater becomes evenly dispersed before it flows into the drain bucket, so as to destroy the conditions to form eddies and isolate the air from entering, when the system would present the full pipe flow state. The siphon roof drain could reach the full flow state in the condition of the smaller water depth before the drain, so as to effectively reduce the ponding depth of the roof (roof gutter) and reduce the roof load.

Since the siphon system rapidly discharges the rainwater in the full flow state, the design must ensure the consistency of the water discharge of all the roof drains in the system; and at the same time, the inflow water loss for each transition section from the roof drain to the outlet must be accurately calculated, so as to ensure the consistency of the water discharge state of each roof drain.

As the core product of the system, it adopts the unique backward eddy current device, in which the rainwater becomes evenly dispersed before it flows into the drain bucket, so as to destroy the conditions to form eddies and isolate the air from entering, when the system would present the full pipe flow state. The siphon roof drain could reach the full flow state in the condition of the smaller water depth before the drain, so as to effectively reduce the ponding depth of the roof (roof gutter) and reduce the roof load.

Made of silicon-aluminum alloy material, it is applicable for various different environments. The fairwater grating separation distance of continuous improvement could not only ensure the inflow water flow, but also prevent large sundries from entering into the system.

With the silicon-aluminum alloy material and the unique backward eddy current design, it could make the rainwater smoothly enter into the System.

With the silicon-aluminum alloy material and the unique backward eddy current design, it could make the rainwater smoothly enter into the System.

Made of the stainless steel material, the rectifier shall be put inside the sink drain bucket, so as to effectively reduce the ponding depth of the roof (roof gutter).

Such outlet tail pipes as of different materials should be selected according to the difference of the pipes to be used. There are HDPE tail pipe, stainless steel tail pipe and groove-connected stainless steel tail pipe.

| Model of Roof Drain | Optimum Flow Range | Dimension of Roof Reserved Hole |

| YG50 | 6~13 L/s | Φ200mm |

| YG65 | 13~24 L/s | Φ300mm |

| YG80 | 24~30 L/s | Φ300mm |

| YG100 | 30~42 L/s | Φ300mm |

| YG125 | 42~71 L/s | Φ240mm |

| YG150 | 70~120 L/s | Φ240mm |

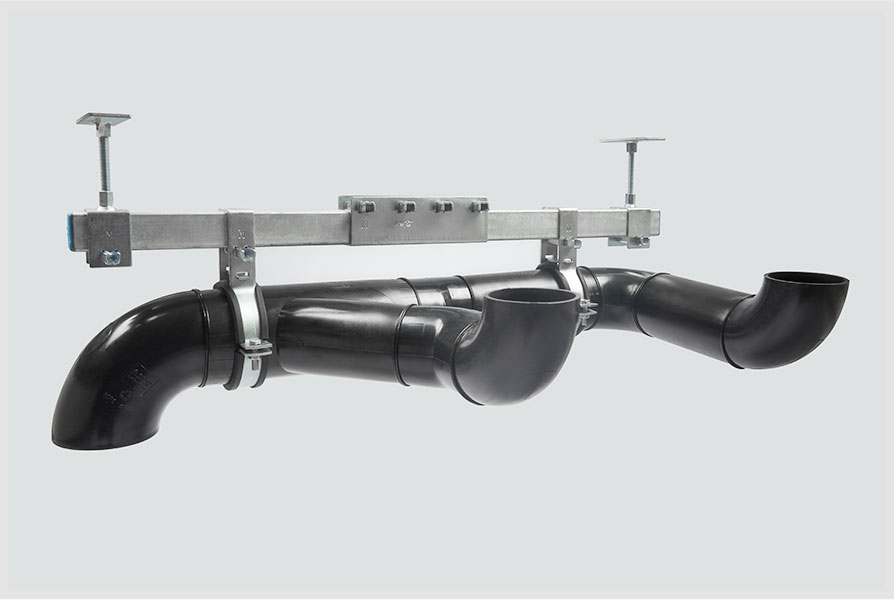

The high density polyethylene pipe is made of polyethylene as the main raw material, with the addition of a handfwwul of such materials as of the antioxidant, ultraviolet-resistant absorbent and pigment. As the most common pipes used for the siphonic rainwater drainage system, it has such characteristics as of light weight, convenience for transportation and construction, and perfect sealing performance.

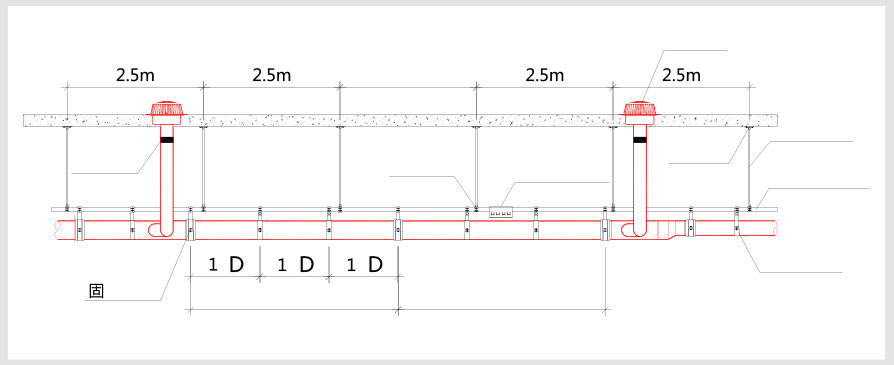

The fixed system has been developed in allusion to the requirements for the special installation of the HDPE pipes applied to the siphon system. The inside of the hanging pipes of the siphonic rainwater drainage system presents the negative state. In order to avoid the air leakage of the system, the system would set up no expansion joint. Tidelion would use the “fixed installation” to limit the stretch mode of the pipeline, in which the axial stress caused by the temperature change of the HDPE pipes would directly be transmitted to the parallelly-installed square steel pipes through the fixed points of the fixed pipe clamp. Through the practical experience in the rainwater drainage system, the maximum working temperature difference of the fixed system can reach 50℃

Want to mount an efficient rainwater harvesting system at your rooftops? Contact the leading firm of China, Beijing Tidelion Science and Innovation Group Co., Ltd., as we can design a proper Siphon drainage system at the rooftops of your industries, as well as commercial and residential buildings. This drainage system we construct is effective in draining the flow of heavy rainfalls quickly and efficiently. We are a team of professional Siphon drainage system manufacturer that has all the expertise in this field, and we know how to carefully balance the overall system at the most complex places. This is why the premier siphon rainwater bucket manufacturer has dealt with many projects for buildings with large footprints, including train stations, retail stores, warehouses, airports, and distribution centers. You would be glad to learn that the services of the siphon roof drainage manufacturer are not limited to China only, but we also reach our global clients.

We, as your trusted siphon system solution provider, can construct the most innovative design of the drainage system with the least site disturbance. Let’s explore here why you should avail of the services from the siphon drainage system manufacturer.

Tidelion has become a well-known corporate in a short period because of the hard efforts of our highly skilled siphon roof drainage manufacturer. Besides offering you a well-constructed and highly efficient drainage system, we also promise to provide you the best ever services. We complete the project in the least time possible and without troubling our clients in any way, which is why we are famous as the most reliable siphon system solution provider on all the global platforms. The best part to excite you more is that we construct this optimal system at very affordable rates for our premium customers.